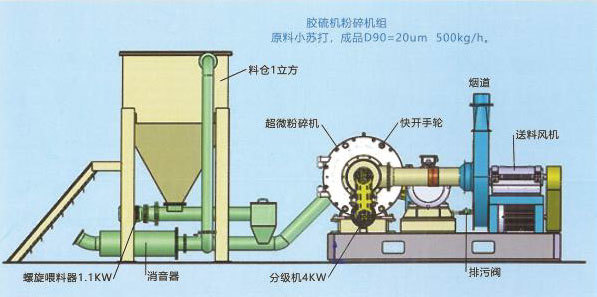

BH-Baking Soda Mill

Key words:

BH-Baking Soda Mill

Classification:

Mobile:

Email:

BH-Baking Soda Mill

Working principle

Sodium chloride carbonate (baking soda) raw materials are evenly fed into the pulverizer for ultra-fine grinding through the quantitative feeder at the lower part of the silo. Products with particle fineness (D90:20um or flexibly adjust product particle size according to deacidification requirements) are delivered to the flue gas pipeline by the high-pressure fan and injected into the flue gas. Rapid chemical reaction with acid-containing flue gas. Sodium chloride carbonate decomposes at high temperature to produce sodium carbonate NaCO,HO and CO. The newly generated sodium carbonate Na.CO. It has high reactivity at the moment of generation and can efficiently react with acidic substances in the flue gas.

Performance characteristics

Using German technology, high-precision mechanical pulverizer, special for sodium bicarbonate desulfurization, suitable for 325-5000 (45um-25um). The design is durable and has lower investment and operating costs than other flue gas purification methods. Can be in the case of low temperature. Highly efficient crushed sodium bicarbonate (baking soda. NaHCO3). Widely used in flue gas dry purification collar city. In municipal waste treatment, toxic waste treatment, biofuels, power plants, cement plants, ceramic industry, non-metallic industry, glass manufacturing industry, steel mills and other industrial waste incineration, hazardous waste incineration, sludge incineration, all kinds of coke ovens and other industrial waste gas, all contain acidic substances, such as SO2HCI, etc., deacidification with baking soda (sodium bicarbonate) will meet the stringent requirements of environmental protection. The cost is still very low. More and more wide application.

Related Products